Industrial control and maintenance

Achieving operational excellence

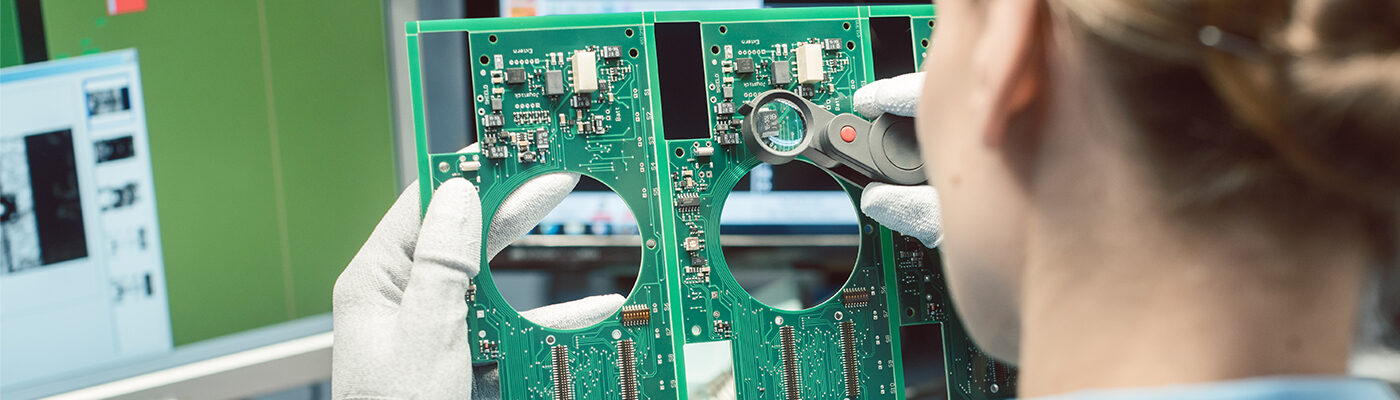

Manufacturers seek to optimise quality management and efficiently identify defective parts during the production or maintenance cycle because they can lead to potential malfunction and generate significant additional costs.

An average of 15% of the turnover is spent on extra costs due to poor quality, and the average cost of a product recall sits around €1.1M.

Automating the control process

If a part becomes defective, it is necessary to evaluate the defects as soon as possible in order to know whether it should be repaired or replaced. Manufacturers are looking for automated solutions, to complement manual inspection, to save time and increase the robustness of the detection of a missing, damaged or added elements.

Increasing efficiency in both mobile and static conditions

These detection solutions must be easy to deploy and portable in order to adapt to the different configurations of the production areas, and operate an integrity control on objects of all dimensions, from electronic cards to large structures.

Portability allows the control of elements that are difficult to access due to their shape, their volume, or the conditions of intervention (outdoors, outside a production line for example).

Compliance inspection with computer vision for industrials :

Quality control and maintenance using visual technology

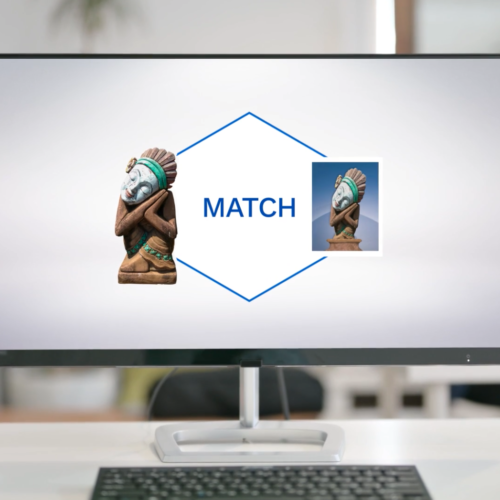

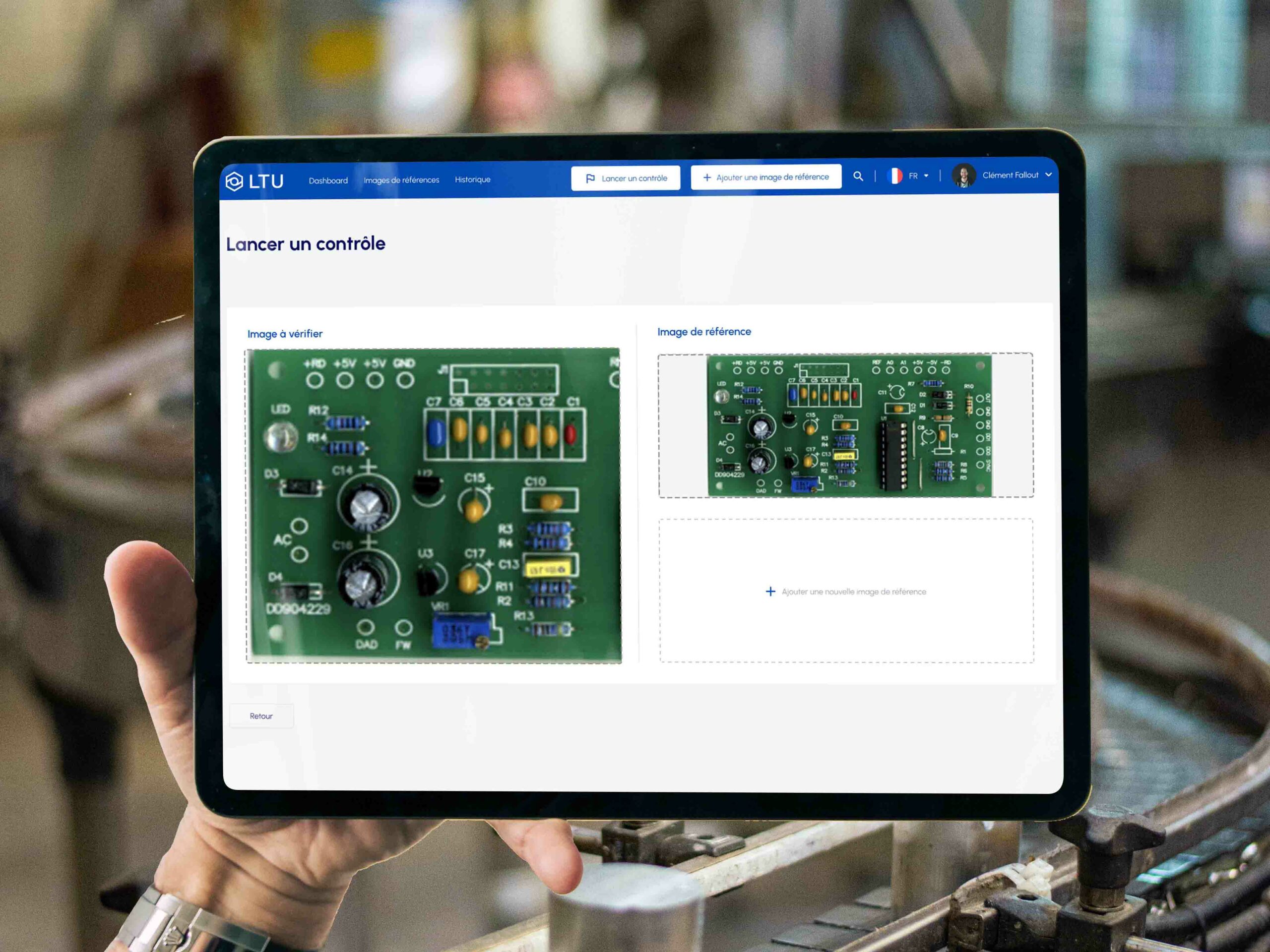

How does it work? LTU’s Change Detection technology allows for a real-time fine image comparison between industrial components, and automatically identify differences such as addition or removal of components, defect, etc.

When a deviation between two pieces is detected, the manufacturer is alerted and the tool displays the areas where production discrepancies have been identified.

Make quality and maintenance inspection accessible with computer vision

Open API

LTU’s quality control and maintenance solution is easy to deploy thanks to its open API. It is flexible and portable and does not require any software installation, allowing immediate availability of visual processing technology.

SaaS or OnPremise

You need a solution that ensures the confidentiality of your data? Choose the OnPremise mode, with local integration of our technology. The technology is also available OnDemand, for a very fast implementation of your quality control and maintenance solution.

Ready-to-use tool in mobility

The quality control and maintenance can be done from a mobile or static station, thus allowing to answer the various configurations of the production lines and uses in mobility.

A team of experts

The ease of integration is guaranteed thanks to the dedicated support team and our engineers specialized in computer vision.